Note that kits are premeasured for convenience.

If left in the pail too long, the product will cure at an accelerated rate rendering it useless. Once A and B are mixed, the catalyzed product should be placed on the floor immediately. Staging is critical so that Part “A” and Part “B” are not confused with one another or mixed too far in advance. Organize mixing station that neither has to relocate, nor block the progress of applications. NOTE: Mask all areas requiring protection product will stick to just about everything. Ideal room temperature is 78 degrees and 50% relative humidity. DK 700 should be acclimated to room temperature, before application. After establishing room dimensions, before mixing commences, place a short piece of masking tape on the wall to correspond to the “distance” one gallon should cover. Track coverage rate for each gallon (3.8 liters). Refer to SDS. Work across the narrowest dimension of an area where practical. Work to an exit from the wet product. Select appropriate PPE (personal protection equipment).

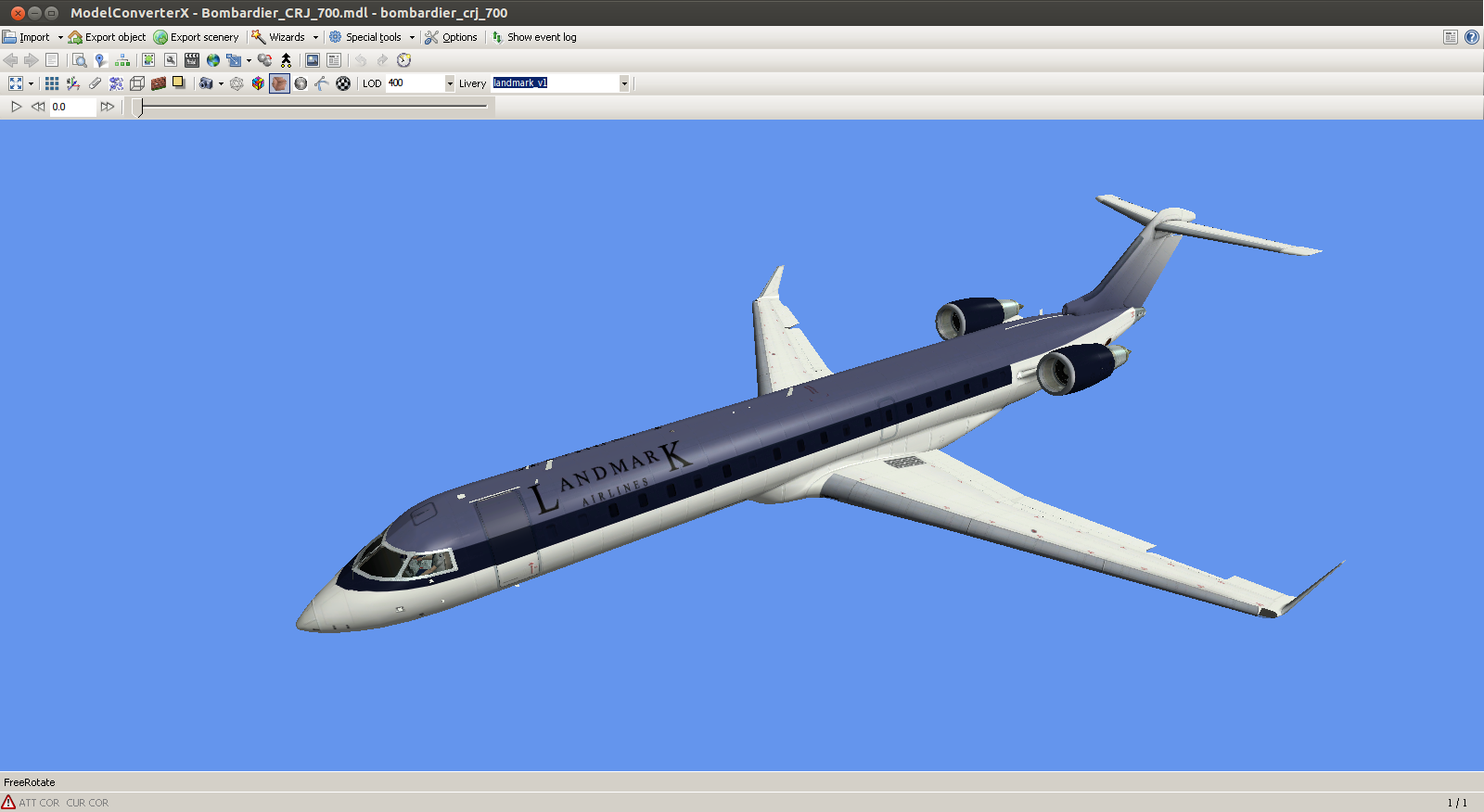

#Project opensky crj 700 paint how to#

How To Apply DK 700 Concrete Moisture Barrier and Vapor BlockerĪpply when surface and ambient temperatures range between 50 F (10 C) and 90 F (32 C) and will remain that way for 24 hours. This product is not a shortcut for poor surface preparation. The surface must be clean, sound, and profiled, as for all specialty sealers. An exception would be for moisture limits which are treated by DK 700. The principles for surface preparation for DK 700 are addressed with the required surface preparation for the Dura-Kote system selected, see TDS of that system. Better mechanical properties (including flexural and tensile strength).DK 700 offers these advantages when applied in advance of any Dura-Kote Coatings: Bond strength exceeds that of traditional epoxy primers.

It can also and under applications of VCT, linoleum, and carpeting.ĭK 700 penetrates without blistering into the concrete’s porous surface to generate mechanical interlock and superior bonding of Dura-Kote systems that follow its application. This unique water vapor barrier opens up the possibility of applying high-performance resinous coatings, including all Dura-Kote Systems, to uncured or moisture-laden concrete that was never before possible. DK 700 stops water vapor transmission, to less than 1/2 pound per 1,000 sq. Class 1 Concrete Moisture Barrier and Vapor Blocker DK 700 by SureCreteĭK 700 is a 2 component solvent-based urethane primer, 97% solids, low VOC (<40 g/L), class 1 vapor barrier that meets ASTM-E96-E93.

0 kommentar(er)

0 kommentar(er)